Flow Chemistry

Flow Chemistry: Efficiency, Innovation, and Sustainability

Advantages of Flow Chemistry

1. Efficient Production of Specialized Products

Flow chemistry allows for the efficient production of smaller, specialized products. Unlike traditional batch processes, it offers precise control over reaction conditions, ideal for niche or customized chemicals. This enables companies to develop tailored products that meet specific customer needs.

2. Reduced Dependency on External Suppliers – De-Risking your Supply Chain

Flow chemistry enables local production, reducing reliance on External suppliers. Its flexibility and scalability shorten supply chains and enhance production control, cutting transport costs, delivery times, and mitigating risks of supply disruptions or geopolitical uncertainties.

3. Cost-Effective Manufacturing

Flow chemistry is cost-effective for production. Continuous processing optimizes raw material and energy use, lowering production costs. It allows quick adjustments for different products without significant downtime, benefiting companies offering diverse product ranges without large inventories.

4. Positive Environmental Footprint

Flow chemistry is more environmentally friendly than traditional methods. Continuous processing and precise control minimize byproducts and waste. It also uses safer reagents and solvents, reducing environmental impact, helping companies achieve sustainability goals.

5. Faster Production Times

Flow chemistry significantly reduces production times. Continuous reactions lead to quicker product turnaround, enabling faster market entry and greater responsiveness to market changes and customer demands. This is particularly advantageous in time-sensitive industries.

Discover the Benefits of Taros' Flow Chemistry Solutions

Low Entry Barrier

Rapid Synthesis Development

Efficient Process Development

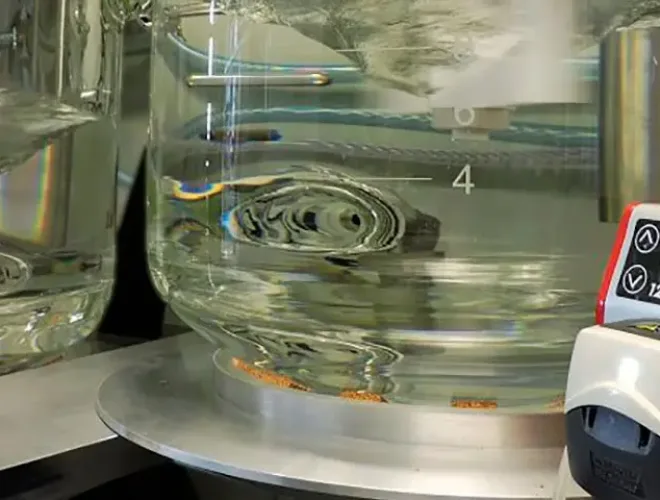

No upfront investment in Flow Chemistry equipment is required. Taros’ state-of-the-art R&D laboratories are equipped with cutting-edge Ehrfeld microreactors.

Quickly develop and validate flow-compatible syntheses.

Easily create cost-effective, flow chemistry-compatible processes.

Combined Expertise

Swift Proof-of-Concept

Scalability

Benefit from the synergy of Taros’ experienced synthesis and process development chemists and Ehrfeld’s seasoned microreactor engineering team.

Obtain rapid proof-of-concept for selected flow processes.

Seamlessly scale from R&D lab to production levels of up to 20,000 tons per year.

Safety

Standards Complaince

Project Managment Excellence

Improve chemical production safety for pharmaceuticals, specialty, and fine chemicals.

Expertise in hybrid batch and flow systems, production scaling, and compliance with ATEX, CE, and cGMP standards.

Benefit from clear FTE project layouts with budget overviews, decision points, expert consultation, and bi-weekly reporting with the Taros-Ehrfeld Expert team.

Looking for Efficiency, Innovation, and Sustainability?

Custom Synthesis

Chemical Services

Chemical Process Development

We are transforming your ideas into products – Serving the value chain from early discoveries and R&D chemistry in the laboratory to pilot scale for your…